304 Stainless Steel

Material Summary

Corrosion resistance is one of the primary reasons to choose type 304 steel for your stainless steel wire products. It contains a minimum of 18% chromium, providing superior resistance to corrosion and oxidation. To enhance these properties further, we electropolish the finished product, which greatly enhances corrosion resistance and provides additional benefits.

It also contains a minimum of 8% nickel and is sometimes referred to as 18 8 stainless, which is a reference to its 18% chromium and 8% nickel content. The nickel content provides hardness and strength for stainless steel wire products.

Type 304 stainless steel is an austenitic grade of stainless steel. The term “austenitic” is a reference to its face centered cubic crystalline structure. It is essentially non-magnetic. However, during cold working, it can become magnetic.

18 8 stainless is so common in stainless steel wire forms because it satisfies several requirements.

- Corrosion Resistance

- Hardness

- Longevity

- Formability

- Weldability

- Ductility

304 Stainless Steel

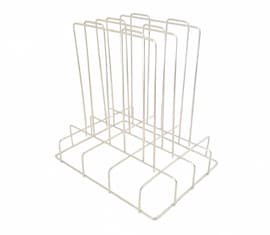

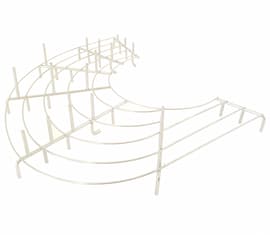

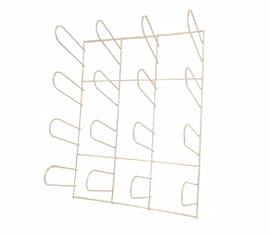

Type 304 stainless steel is used in several different industries for a wide range of products.

Industries

304 stainless steel wire products are found in many different industries. It is common to see 304 stainless steel wire forms in the medical, aerospace, automotive, and foodservice industries.

Composition

304 stainless is an alloy composed of the following elements.

| Type 304 Stainless Steel Composition, % | |||||||

| Cr | Ni | C ≤ | Mn ≤ | P ≤ | Si ≤ | S ≤ | Fe |

| 18 – 20 | 8 – 10.5 | .08 | 2 | .045 | 1 | .03 | Balance |

Tensile Strength

Tensile strength measures the amount of stress that one square inch of material can endure before breaking. It is commonly measured in pounds per square inch. A 1” x 1” material that is 100,000 PSI can endure 100,000 pounds before breaking. Wire is usually drawn using a PSI that is expressed as a range (e.g., 80,0000 to 100,000 PSI). Because wire is drawn at different diameters, the breaking load will depend on the tensile strength and the wire diameter. As you would expect, the larger wire diameters can support a heavier load.

Cost

304 stainless steel has a higher cost when compared to carbon steel wire. The higher cost is driven by the price of nickel and chromium. However, these costs are somewhat mitigated because we purchase it in large quantities and because of the large volume of 18 8 stainless produced by rod mills around the world.

Advantages and disadvantages

304 Stainless Steel

Advantages

Corrosion Resistance

Superior resistance to corrosion and oxidation.

Formability

Relatively easy to bend, flatten, and shape.

Weldability

Relatively few welding issues.

Disadvantages

Cost

Higher cost relative to carbon steel. However, we purchase in such large quantities that we can often provide the same wire product in 304 stainless steel at the same or lower price point compared to carbon steel.

304 Stainless Steel