Welded

Wire Products

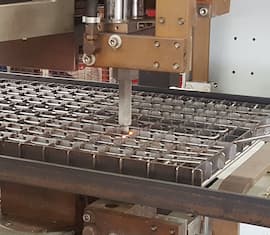

Equipment

Robotic Welding

Our robotic welder can handle large volume production.

MIG Welding

Our MIG welders provide efficient welding solutions.

TIG Welding

We use our TIG welders for clean, cosmetic welds.

Custom

Equipment

Welded Wire Products

We work with companies from all over the world to make everything from simple to complex wire products. Our welding technicians go through a rigorous training program to ensure that we are maximizing our use of technology and automation. We continue to reinvest in the latest welding equipment to ensure that we stay on the cutting edge of technology and automation.

All of this translates into consistency, efficiency, and short lead times. Put our experience and skill to work for you.

As a metal fabricator with many years of experience, our engineers have developed a variety of custom-built tooling for creating welded wire forms. Our custom metal fabrication solutions meet diverse needs, allowing us to serve many industries with the latest technology and processes. Our commitment to you is based on a simple value proposition: Excellent quality at competitive prices.

Resistance Welds

A simple form of welding that creates welded wire products efficiently.

MIG Welds

An arc weld that adds filler material to join two pieces of wire to form welded wire forms.

TIG Welds

An arc weld that uses little or no filler material. A clean, cosmetic welded wire form is created.

Combination of Welds

For most of our products we use a combination of resistance welds, MIG welds, and TIG welds.

Weld Selection

Choosing the right types of welds is an important part of ensuring a successful wire product. Pronto is an experienced metal fabricator, so our engineers select from resistance welds, MIG welds, and TIG welds depending on how the product will be used.

Each one of the welds that we work with has advantages. Contact us for more information on the types of welds that we use or that are best for specific welded wire products. Metal fabrication is our passion!

From small runs to large volume production, we have the right solutions for your custom metal products.