1008 Carbon Steel

Material Summary

Whether cold drawn wire or cold rolled sheets, this steel is widely used because of its formability, durability, and weldability. Processing through cold drawing or cold rolling improves the yield strength and hardness of the material. You can find 1008 carbon steel wire and sheet metal products in a wide range of industries. As a result, Pronto makes many steel wire forms from mild steel.

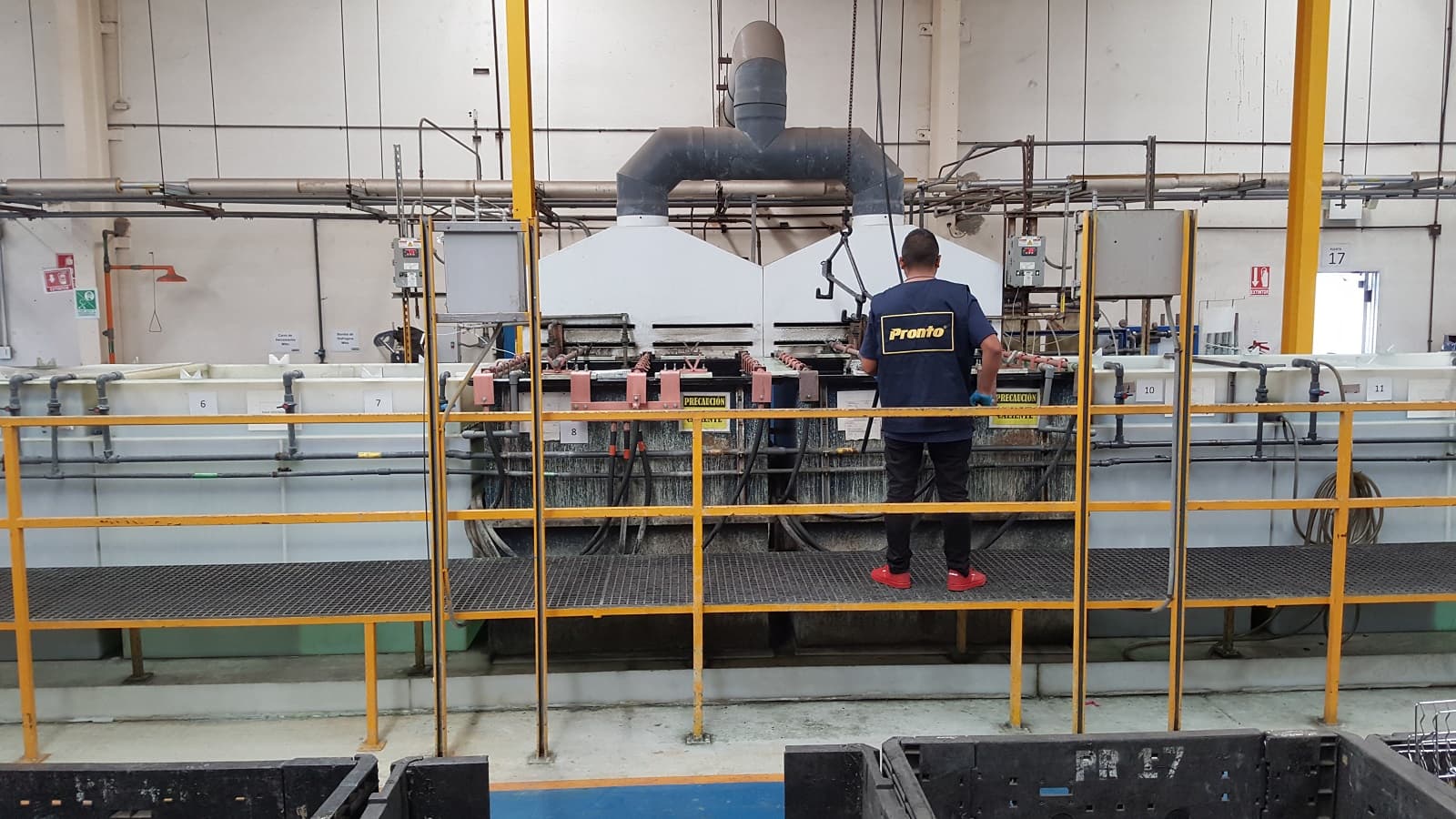

Some type of metal finishing is usually required for the products that we manufacture out of 1008 steel. The coating is usually required to protect the base metal from corrosion. Many different types of metal finishings are available. Thermoset and thermoplastic powders are some of the common options.

- Formability

- Weldability

- Longevity

1008 Carbon Steel Specifications

Industries

1008 carbon steel is found in a wide range of industries. It is one of the most common types of carbon steel.

Composition

1008 carbon steel is an alloy composed of the following elements.

| 1008 Carbon Steel Composition, % | |||||||

| Mn | C | S | P | Fe | |||

| .30 – .50 | .10 | .05 | .04 | Balance | |||

Tensile Strength

Tensile strength measures the amount of stress that one square inch of material can endure before breaking. It is commonly measured in pounds per square inch. A 1” x 1” material that is 100,000 PSI can endure 100,000 pounds before breaking. Wire is usually drawn using a PSI that is expressed as a range (e.g., 80,0000 to 100,000 PSI). Because wire is drawn at different diameters, the breaking load will depend on the tensile strength and the wire diameter. As you would expect, the larger wire diameters can support a heavier load.

Cost

This material is very common and relatively inexpensive. It is a less expensive option relative to stainless steel alloys.

Advantages and disadvantages

1008 Carbon Steel

Advantages

Cost

An inexpensive steel alloy.

Formability

Relatively easy to bend, flatten, and shape.

Weldability

Relatively few welding issues.

Disadvantages

Corrosion

Susceptible to corrosion.

Ductility

Less ductile than stainless steel.

1008 Carbon Steel