Initial Design

Product design is the first step when developing high quality custom wire products and custom metal products. We blend years of engineering knowledge with creative design to efficiently design products that meet your specifications. All of this is possible through our proven and innovative design process and extensive wire forming experience. Here’s how our design process works.

“Design for Efficiency”

Our design engineers start by evaluating the application and selecting metal alloys that will best suit the product’s end-use. Part of this process is assessing different wire diameters and types of wire, sheet metal, wire mesh, and tube that will ensure efficient production.

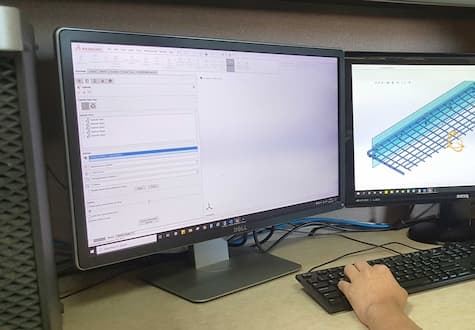

CAD Simulation

Pronto’s product design engineers and drafting engineers use CAD simulation software when designing custom wire products to ensure that your product will work as intended. That includes testing in a simulated environment using tolerance analysis and stress tests.

Revise and Retest

After simulation, we review the design and make adjustments based on potential issues that we see during the initial design phase. Some of these changes relate to the base design, and others relate to changes that will result in more efficient production in the future.

Production Design

After the initial design, Pronto’s engineers design fixtures and develop the manufacturing process for your custom wire product or custom metal product. The production engineers are already familiar with the product because of their involvement in the initial design phase. The next step in our process is to make sure the fixtures and manufacturing process build on our initial design.

Design Process Methods

Pronto’s engineers work closely with each other and the customer to ensure that we are meeting specifications for your custom metal fabrication project in the most economical manner possible. Our design engineers and drafting engineers understand that designing custom metal products is not done in a vacuum. A collaborative team approach achieves the best ideas, processes, and results.

Teamwork

Teamwork across our engineering team — and with our client — is integral to the success of each and every custom product. Brainstorming, open communication, and a collaborative environment open the potential for consistent success across a wide range of wire and metal parts and a wide range of industries.

Client Service

We never lose sight of client service. Our client’s success is our success. We bring our skill, talent, energy, and enthusiasm to the plant so that we can better serve our clients. As a byproduct, it also makes our product design engineers better teammates and makes designing custom metal products enjoyable.

Passion

Designing custom wire products is our passion! Whether it’s a big project or a small project, we never lose the joy in bringing products to life. We celebrate when an employee reaches a new level of skill. Whether it’s CNC operators, metal finishers, or CAD experts, we celebrate every new milestone for our employees.

Respect

Our design engineers approach each custom product design with respect. For each other, for our clients, and for the effort that each of us brings into the plant each day. Every day.

Pronto’s engineers work closely with each other and the customer to ensure that we are meeting specifications for your custom metal fabrication project in the most economical manner possible. Our design engineers and drafting engineers understand that designing custom metal products is not done in a vacuum. A collaborative team approach achieves the best ideas, processes, and results.